| Stainless Steel Types | Applications |

|---|---|

| 302HQ, 305, 410, 430 | screw |

| 302, 304H | wire rope, spring, vibrating screen |

| 303 | free cutting |

| 304M, 304L | wire mesh |

| 308 | welding |

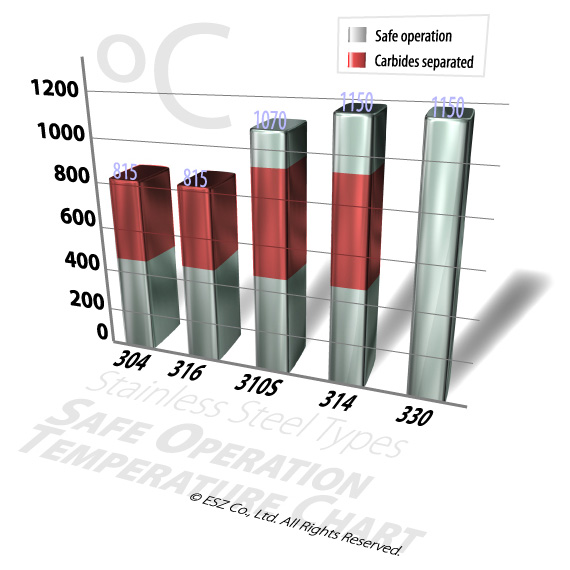

| 310S, 314 | products need to resist high temperature |

| 316, 316L | products need to resist acid corroison |

Major Types of Stainless Stell:

According to chemical composition, stainless steel can be dividedinto two major types:

1. The chromium-nickel grade, with the AISI/ASTM specification is usually identified as "3" series: 302, 302HQ, 303, 304H, 304L, 305, 308, 310S, 314, 316, and etc.

2. The chromium grade is identified as "4" series: 410, 420, 430 in AISI/ASTM.

可以向右滑動查看

| Class | AISI/ | Chemical Compositions (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ASTM | C | Si | Mn | P | S | Ni | Cr | Mu | Cu | |

| Cr-Ni Grade |

302 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 8.00~10.00 | 17.00~19.00 | - | - |

| 302HQ | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.040 | ≤0.030 | 8.50~10.50 | 17.00~19.00 | - | - | |

| 303 | ≤0.15 | ≤1.00 | ≤3.50 | ≤0.20 | 0.25~0.35 | 8.00~10.00 | 17.00~19.00 | - | - | |

| 304H | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 8.00~8.90 | 18.00~20.00 | ≤0.60 | - | |

| 304HC | ≤0.06 | ≤1.00 | ≤2.00 | ≤0.040 | ≤0.015 | 8.00~10.00 | 18.00~19.00 | - | 1.00~3.00 | |

| 304L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 8.00~12.00 | 18.00~20.00 | - | - | |

| 304L(JIS) | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 9.00~13.00 | 18.00~20.00 | - | - | |

| 304M | ≤0.06 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 8.90~10.00 | 18.00~20.00 | - | - | |

| 304S | ≤0.06 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 10.00~10.50 | 18.00~20.00 | - | - | |

| 304J3-S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 8.00~10.50 | 17.00~19.00 | - | 1.00~3.00 | |

| 305 | ≤0.12 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 10.50~13.00 | 17.00~19.00 | - | - | |

| 305J1 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 11.00~13.50 | 16.50~19.00 | - | - | |

| 310S | ≤0.08 | ≤1.50 | ≤2.00 | ≤0.045 | ≤0.030 | 19.00~22.00 | 24.00~26.00 | ≤0.50 | - | |

| 314 | ≤0.25 | 1.50~3.00 | ≤2.00 | ≤0.045 | ≤0.030 | 19.00~22.00 | 23.00~26.00 | - | - | |

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 10.00~14.00 | 16.00~18.00 | 2.00~3.00 | - | |

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 10.00~14.00 | 16.00~18.00 | 2.00~3.00 | - | |

| 316L(JIS) | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 12.00~15.00 | 16.00~18.00 | 2.00~3.00 | - | |

| Cr Grade |

410 | 0.08~0.15 | ≤1.00 | ≤1.00 | ≤0.040 | ≤0.010 | ≤0.60 | 11.50~13.00 | - | - |

| 430 | ≤0.08 | ≤1.00 | ≤1.00 | ≤0.040 | ≤0.010 | ≤0.60 | 16.00~18.00 | - | - | |

- AISI = American Iron & Steel Institute;ASTM = American Society for Testing and Materials

- JIS = Japanese Industrial Standard

- Safe Operation Temperature Chart

Specifications Required Upon Ordering:

1. Stainless steel type

2. Diameter (range within 0.15mm to 16mm.)

3. Tensile strength

4. Surface (dull or birght finish.)